Lean Management: goals and principles of an Agile approach that optimizes workflows through continuous improvement

Estimated reading time : 7 minInspired by the Japanese production system, Lean Management is an approach to organizing and managing work that aims to eliminate waste that harms the efficiency and performance of a team, project, or company. Its goal is to maximize quality while reducing cost, time, and resources used. To achieve this, it relies on customer integration in processes to identify what truly creates value, as well as on Kaizen (continuous improvement) and on optimizing the organization’s practices and capabilities.

Problem-solving happens directly on the shop floor, involving the people closest to the work, who are best placed to identify sources of waste and propose suitable solutions. This approach requires ongoing learning in both productive and non-productive activities. More than a method, Lean is a genuine philosophy that demands a shared commitment from teams and leadership, grounded in common values and close collaboration. Every success is a learning opportunity, and every problem a chance to improve. One of Lean’s key challenges is finding the right balance between reducing waste and maintaining good working conditions.

Lean’s objective: eliminate common project management problems

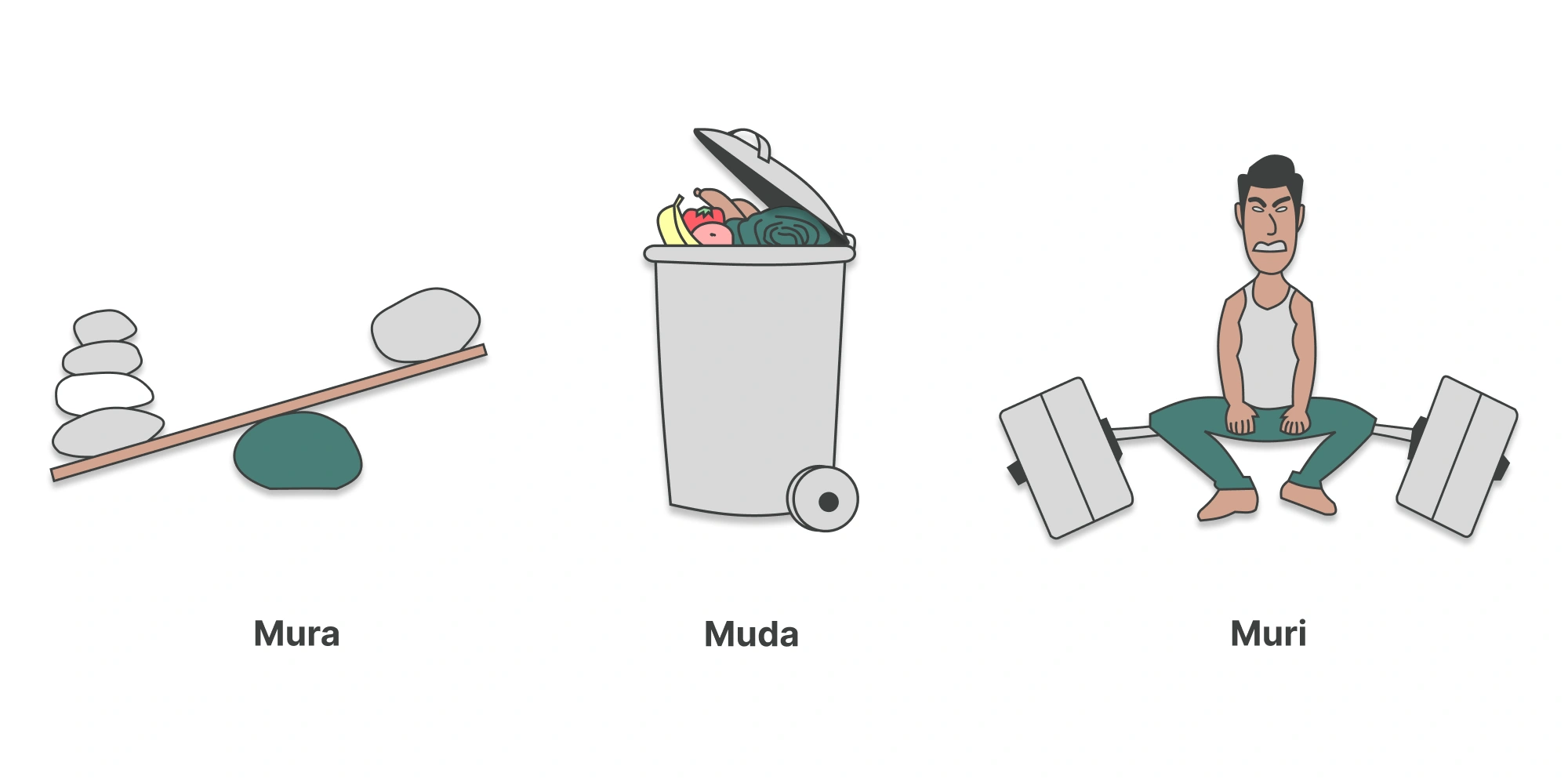

Lean Management seeks to eliminate three major sources of problems in project management:

Muda: waste

In Lean Management, waste refers to anything that does not add value to the product. It can take eight distinct forms:

1. Overproduction

2. Waiting times

3. Defects, rework, and corrections

4. Unnecessary operations and use of unsuitable tools

5. Excess handling and transportation

6. Unnecessary motion

7. Excess inventory

8. Underuse of people’s skills and knowledge

Muri: overburden

Overburden results from processes that are not calibrated to actual capacity. It appears as:

1. Workload exceeding available headcount

2. Training that does not match required skills

3. Premature wear of equipment and tools due to excessive use

4. Insufficient inventory to maintain a stable production flow

Mura: unevenness/variability

Variability refers to fluctuations in processes that create imbalance, causing peaks and troughs in workload and under-/over-utilization of resources. It can appear at several levels:

1. Workload: alternating periods of high pressure and low activity, with uneven task distribution across teams.

2. Production: poor control of lead times and quantities (supply or execution), leading to inconsistent flow.

3. Processes: lack of standardization, where people assigned to the same task execute it differently and at inconsistent pace.

The 5 basic principles of Lean

To achieve its goals, Lean Management applies five core principles:

Identify product value

Maintain continuous communication with the beneficiary and all stakeholders to understand expectations and needs. The aim is to pinpoint exactly what in the solution delivers real value to the customer and drives interest.

Map the value stream (VSM)

Here, you visualize the end-to-end workflow across the organization. Include all actions and actors involved in the project, then sequence them to identify the essential steps and spot repetition and inefficiency.

Create continuous flow

The goal is to assess each step to detect bottlenecks and analyze their causes. Ensure tasks flow smoothly while essential information circulates effectively within the team, enabling real-time collaboration.

Establish a pull system

In a pull system, work is produced only when there is demand, and resources are mobilized only to meet real, concrete needs. Tasks are limited to ensure a fast, smooth flow. The objective is to regulate intake: no new work starts without proven demand and available capacity, avoiding overburden and overproduction.

Kaizen: continuous improvement

Improve continuously: The four principles above set the Lean foundation, but Lean is neither static nor isolated. Implementation is iterative, aiming at ongoing improvement and a constant quest for perfection. This requires a culture of questioning and steady optimization.

Conditions for applying Lean Management

Lean Management is ideal for projects with limited resources and repetitive processes from one project to another, where continuous optimization and shorter lead times are needed while maintaining high quality.

It suits organizations with fluid communication between teams and management, where the customer is available to take part in continuous improvement, and where the culture encourages questioning and adaptability in the face of change and challenges.

Lean combines a pragmatic approach with a culture of continuous improvement to streamline processes, increase team engagement, and optimize end-to-end workflows.

Discover other project management methods

Orchesia: laying the groundwork for continuous improvement in your organization

With Orchesia, we are building project construction and tracking software designed to help you structure, plan, and optimize your processes.

Thanks to our visual methods, you can map your project and its value stream to ensure smooth, effective tracking.

At Orchesia, we believe that a well-constructed project enables learning and improvement. That’s why our dashboards and project histories help you analyze what worked and what needs to improve.

By saving a project as a template, you capitalize on past experience: reuse an optimized structure for future projects, avoid starting from scratch, and keep improving your workflow.

Try our project management software Orchesia free for two weeks, no commitment!